This machine is a special heavy-duty

Cnc Roll Lathe, mainly used for processing roll body hole profiles in steel mills, and can also turn the outer circle and roll neck of rolls, and can turn parts similar to rolls. The machine has advanced design, reliable performance, easy operation, and can meet the processing needs of precision parts.

The machine tool is well-made, has excellent performance, and has a long accuracy retention period. It is suitable for long-term, continuous, and high-load processing. The machine tool has good static, dynamic, and thermal stiffness, stable and reliable operation control, a simple, smooth, and beautiful operating interface, and is easy to maintain.

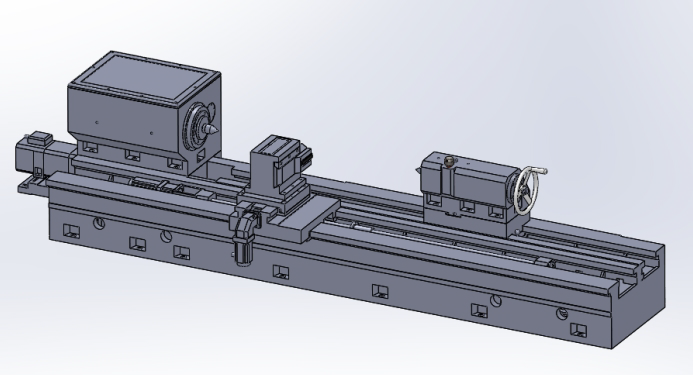

Overall layout and composition of the machine:

This CNC heavy duty

Roll Lathe adopts the layout of HT300 castings and horizontal lathes. It consists of functional components such as bed, headstock, tailstock, slide, protective device, and electronic control system, as shown in the figure below:

Performance characteristics:

● CK8450 CNC Heavy Duty Roll Lathe has advanced and reliable structure, mature technology, good appearance, and complete and reliable safety protection devices.

● The bed large slide rail adopts 3+1 rectangular positioning rail, and the rail surface adopts high-frequency quenching. The longitudinal and transverse feed motion rails of the tool holder adopt high-rigidity rectangular rails, combined with the high-rigidity tool row on the frame tool holder, which improves the high rigidity and stability of the machine tool during cutting processing.

● The machine tool is equipped with a SIMENES828D CNC system. The main drive is driven by a servo motor, and the longitudinal (Z axis) and transverse (X axis) are ball screw drives. The longitudinal and transverse movements of the tool holder are driven by AC servo motors.

Technical parameter:

| Maximum machining diameter | Φ500mm |

| Workpiece length | 2500mm |

| Spindle speed | 1rpm~200rpm |

| Spindle center height | 1030mm |

| Spindle motor power | 22KW |

| Z-axis motor power | 3.2KW |

| X-axis motor power | 2.1KW |

| Z-axis feed speed range | 1~6000mm/min |

| X-axis feed speed range | 1~3000mm/min |

| Distance from spindle center to guide rail | 400mm |

| Distance from spindle center to tailstock center | 2500mm |

| Distance from spindle center to carriage | 205mm |

| Diameter of spindle end chuck | Φ500 |

| Spindle center | Morse No. 6 |

| Tailstock center | Morse No. 6 |

| Tailstock center load | 3500Kg |

| Tailstock sleeve stroke | 200mm |

| Surface roughness of fine turning outer circle | ≤Ra0.8μm |

| Fine turning outer circle roundness | ≤0.01 mm |

| Minimum unit of longitudinal and lateral movement | 0.001 mm |

| X-axis ball screw nominal diameter | Φ40 |

| Z-axis ball screw nominal diameter | Φ63 |

| Positioning accuracy A (X axis) | 0.012mm |

| Positioning accuracy A (Z axis) | 0.045mm |

| Repeat positioning accuracy R (X axis) | 0.007mm |

| Repeat positioning accuracy R (Z axis) | 0.01mm |

| Reverse difference B (X axis) | 0.006mm |

| Reverse difference B (Z axis) | 0.012mm |

| Installation size of machining tool | 200*32*32mm |

| Machine size (length*width*height) | 5750*1850*1800mm |

| Net weight of machine tool | 11000Kg |