-

In the metal fabrication industry, Vertical Machining Centers (VMCs) are indispensable for achieving efficient milling operations, enabling operators to cut and shape materials with remarkable precision while minimizing manual intervention. VMCs come with a host of advantages, such as quick and easy setup processes, lower initial costs compared to their horizontal counterparts, and user-friendly operation, making them perfect for both prototyping and large-scale production runs. Their high ma

-

The article explores the changing landscape of CNC machining equipment within the engine building industry, revealing varied perceptions among shop owners regarding its complexity and cost. While some recognize CNC technology as a significant advancement, others hesitate to adopt it due to fears of change and a lack of understanding. Equipment suppliers argue that CNC is vital for maintaining competitiveness, enabling shops to reduce outsourcing, boost efficiency, and enhance accuracy. The di

-

Thinking about transforming your Vertical Machining Center into the life of the shop? It's not just about having the best equipment; it's about creating an environment where creativity and productivity thrive! Picture this: your

-

Sure! Here’s an engaging and concise summary based on the provided information that captures the essence of the comparisons between horizontal and vertical machining centers, while maintaining a light and humorous tone: "Think vertical machining centers (VMCs) are just for the pros? Think again! Whether you're a seasoned machinist or just starting out, VMCs are like the Swiss Army knives of the machining world—versatile, user-friendly, and perfect for those smaller parts that need a littl

The Importance of Machining Center Maintenance in Modern Manufacturing

Machining Center Maintenance is crucial in today's manufacturing landscape, particularly for companies like Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. As industries increasingly rely on precision machining, regular maintenance ensures optimal performance, reduces downtime, and extends the lifespan of machinery. The trend towards automation and smart manufacturing further emphasizes the need for effective maintenance strategies, as they can significantly enhance productivity and operational efficiency.

Machining Center Maintenance

- manufacturer, factory, supplier from China(Total 12 Products for Machining Center Maintenance)

-

Brand:YICHUANGA horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. The horizontal machining center has the functions of automatically exchanging...

-

Brand:YICHUANGThe profile machining center is a high-performance automated processing equipment. Compared with ordinary CNC machine tools, its processing accuracy and stability have been significantly improved. It can meet customers' processing requirements for...

-

Brand:YICHUANGOur advanced profile machining centers have excellent technology to process aluminum and steel profiles. The machine adopts vertical moving column structure, and is equipped with follow-up tool library, which can meet the efficient processing of...

-

Brand:YICHUANGThe overall structure of the gantry machining center is a portal frame, which is composed of a solid double column and a top beam. The middle crossbeam connects the two columns. This structure provides extremely high stability and rigidity, and can...

-

Brand:YICHUANGVertical machining center is a multifunctional machine tool with high precision and high efficiency. It is an ideal machine tool for processing complex metals. CNC vertical machining center can be used in mechanical manufacturing industries with...

-

Brand:YICHUANGAccording to the different structure and function, the horizontal machining center can be divided into a variety of types: milling machine type horizontal machining center, gantry type horizontal machining center, dividing head horizontal machining...

-

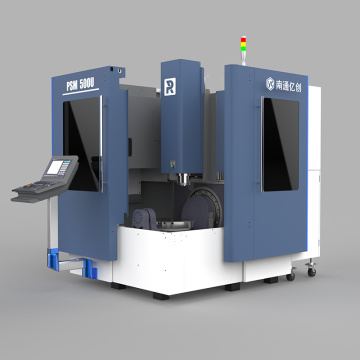

Brand:YICHUANGThe vertical five-axis machining center has multiple machining functions and can process parts of various complex shapes to meet the machining needs of different industries. The main components of the vertical five-axis machining center, such as the...

-

Brand:YICHUANGThe five-axis vertical machining center is equipped with a Siemens CNC system, which can process parts of various complex shapes and meet the processing needs of different industries. The machining center is highly automated, efficient and stable....

-

Brand:YICHUANGAs a high-performance automated processing equipment, the gantry machining center has become a key equipment for many companies to improve production efficiency and reduce costs due to its excellent performance and wide range of applications. On the...

-

Brand:YICHUANGThe vertical machining center is a high-precision machine tool that can not only complete basic processes such as milling, boring, drilling, and tapping, but also perform complex three-dimensional surface processing and five-axis linkage processing....

-

Brand:YICHUANGPerformance characteristics: ● The 5-axis Vertical Machining Center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, special-shaped parts, etc.; ●...

-

Brand:YICHUANGPerformance characteristics: ● PSL series high precision profile processing center is suitable for military, aerospace, automobile, machinery manufacturing and other industries, and can complete the processing of narrow and long parts; ● CNC Profile...

Key Strategies for Effective Machining Center Maintenance

Implementing a proactive maintenance strategy for machining centers is essential for maximizing productivity and minimizing costs. Companies such as Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. benefit from scheduled maintenance, which includes routine inspections, lubrication, and part replacements. These practices not only prevent unexpected breakdowns but also ensure that machines operate at peak efficiency. Additionally, utilizing predictive maintenance technologies can help identify potential issues before they escalate, further safeguarding production timelines.

| Maintenance Type | Frequency (Months) | Cost (USD) | Downtime Reduction (%) |

|---|---|---|---|

| Preventive Maintenance | 3 | 1200 | 30 |

| Predictive Maintenance | 6 | 1500 | 40 |

| Corrective Maintenance | 12 | 2000 | 10 |

| Emergency Maintenance | 1 | 3000 | 5 |

| Routine Checks | 1 | 500 | 25 |

| Calibration | 6 | 800 | 20 |

Related Information