-

Are you tired of wasting time on CNC parts that break easily? If you're a CNC machining novice facing frequent end mill breakage, you're not alone! Let's dive into some practical advice to turn your machining woes into wins. First off, if you're using a feed rate of .0075 in aluminum, that's quite substantial! Improper torque on the end mill in your ER32 holder might be the culprit behind those frustrating snap-offs. Remember, quality tools are your best friends—skip the cheap alternatives!

-

In the metal fabrication industry, Vertical Machining Centers (VMCs) are indispensable for achieving efficient milling operations, enabling operators to cut and shape materials with remarkable precision while minimizing manual intervention. VMCs come with a host of advantages, such as quick and easy setup processes, lower initial costs compared to their horizontal counterparts, and user-friendly operation, making them perfect for both prototyping and large-scale production runs. Their high ma

-

Are your Cnc Machined Parts letting you down again? If you’re like many in the machining world, you’ve probably faced the frustration of unexpected dimension variations that make you question your equipment—and your sanity. Take Sugumar, for instance, who reported a perplexing 20-micron shift after short b

-

Are you tired of production issues that slow down your business? Elevate your efficiency and quality with our precision CNC machined components! Don’t settle for less; choose our expert solutions to streamline your production process. Reach out to us today to explore how we can tackle your production challenges and enhance your operations. Whether you’re facing complex manufacturing tasks or need expert advice on material selection and machining processes, our skilled team is here to turn

The Future of Machining Center CNC Technology

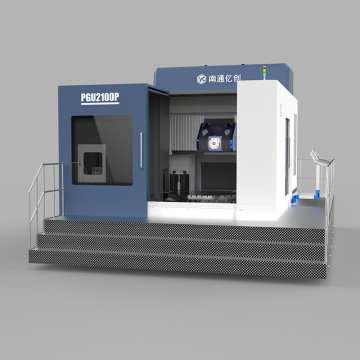

Machining Center CNC technology is transforming the manufacturing landscape, offering precision and efficiency that are crucial in today's competitive market. As industries increasingly adopt automation, the demand for advanced CNC machining centers continues to rise. Companies like Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. are at the forefront of this evolution, providing cutting-edge solutions that enhance productivity and reduce operational costs. The value of Machining Center CNC lies in its ability to streamline processes, improve product quality, and enable manufacturers to respond swiftly to market changes.

Machining Center Cnc

- manufacturer, factory, supplier from China(Total 12 Products for Machining Center Cnc)

-

Brand:YICHUANGCNC vertical turning machining center is a kind of CNC machine tool which integrates many machining capabilities such as turning, milling, drilling and tapping. ● High efficiency: Vertical turning machining centers are usually equipped with...

-

Brand:YICHUANGVertical machining center is a kind of high-precision machine tool, which can not only complete the basic procedures such as milling, boring, drilling and tapping, but also carry out complex three-dimensional surface machining and five-axis linkage...

-

Brand:YICHUANGPerformance characteristics: ● The gantry five-axis machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, casings and other parts; ●...

-

Brand:YICHUANGA horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. The horizontal machining center has the functions of automatically exchanging...

-

Brand:YICHUANGHorizontal machining centers have a variety of types and a wide range of application fields to meet the needs of different industries for high-precision and high-efficiency machining. Performance characteristics: ● Horizontal machining center is...

-

Brand:YICHUANGThe profile machining center is a high-performance automated processing equipment. Compared with ordinary CNC machine tools, its processing accuracy and stability have been significantly improved. It can meet customers' processing requirements for...

-

Brand:YICHUANGVertical machining center is a multifunctional machine tool with high precision and high efficiency. It is an ideal machine tool for processing complex metals. CNC vertical machining center can be used in mechanical manufacturing industries with...

-

Brand:YICHUANGThe overall structure of the gantry machining center is a portal frame, which is composed of a solid double column and a top beam. The middle crossbeam connects the two columns. This structure provides extremely high stability and rigidity, and can...

-

Brand:YICHUANGThe vertical five-axis machining center has multiple machining functions and can process parts of various complex shapes to meet the machining needs of different industries. The main components of the vertical five-axis machining center, such as the...

-

Brand:YICHUANGAs a high-performance automated processing equipment, the gantry machining center has become a key equipment for many companies to improve production efficiency and reduce costs due to its excellent performance and wide range of applications. On the...

-

Brand:YICHUANGAccording to the different structure and function, the horizontal machining center can be divided into a variety of types: milling machine type horizontal machining center, gantry type horizontal machining center, dividing head horizontal machining...

-

Brand:YICHUANGThe five-axis gantry machining center provides excellent five-axis synchronous precision performance for five-axis machining such as mold cutting, high-precision contour finishing, milling, drilling, and tapping. The five-axis gantry CNC machine...

Emerging Trends in Machining Center CNC Applications

The application of Machining Center CNC is expanding beyond traditional manufacturing sectors into areas such as aerospace, automotive, and medical devices. This trend is driven by the need for high-precision components and the ability to produce complex geometries that were previously difficult to achieve. As companies like Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. innovate their offerings, the integration of smart technology and IoT capabilities into CNC machines is set to revolutionize production workflows. This evolution not only enhances operational efficiency but also supports sustainable manufacturing practices.

| Industry | Market Share (%) | Growth Rate (2023-2028) | Key Applications |

|---|---|---|---|

| Aerospace | 25 | 8% | Parts manufacturing, assembly |

| Automotive | 30 | 6% | Engine components, chassis |

| Medical Devices | 15 | 10% | Surgical tools, implants |

| Electronics | 20 | 7% | Circuit boards, housings |

| Energy | 10 | 5% | Turbine parts, generators |

Video

Key Global Players in Machining Center CNC Distribution

The global distribution of Machining Center CNC technology is dominated by a few key players who are shaping the market landscape. These distributors are leveraging advanced manufacturing techniques and supply chain optimization to meet the growing demand for CNC solutions. As industries evolve, the adoption of CNC technology is expected to rise significantly, driven by the need for automation and precision engineering. Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. is among those contributing to this growth, focusing on innovative solutions that enhance performance and sustainability in manufacturing.

Related Information