-

In the metal fabrication industry, Vertical Machining Centers (VMCs) are indispensable for achieving efficient milling operations, enabling operators to cut and shape materials with remarkable precision while minimizing manual intervention. VMCs come with a host of advantages, such as quick and easy setup processes, lower initial costs compared to their horizontal counterparts, and user-friendly operation, making them perfect for both prototyping and large-scale production runs. Their high ma

-

The article explores the changing landscape of CNC machining equipment within the engine building industry, revealing varied perceptions among shop owners regarding its complexity and cost. While some recognize CNC technology as a significant advancement, others hesitate to adopt it due to fears of change and a lack of understanding. Equipment suppliers argue that CNC is vital for maintaining competitiveness, enabling shops to reduce outsourcing, boost efficiency, and enhance accuracy. The di

-

Thinking about transforming your Vertical Machining Center into the life of the shop? It's not just about having the best equipment; it's about creating an environment where creativity and productivity thrive! Picture this: your

-

Sure! Here’s an engaging and concise summary based on the provided information that captures the essence of the comparisons between horizontal and vertical machining centers, while maintaining a light and humorous tone: "Think vertical machining centers (VMCs) are just for the pros? Think again! Whether you're a seasoned machinist or just starting out, VMCs are like the Swiss Army knives of the machining world—versatile, user-friendly, and perfect for those smaller parts that need a littl

The Rise of High Precision Gantry Machining Centers in Modern Manufacturing

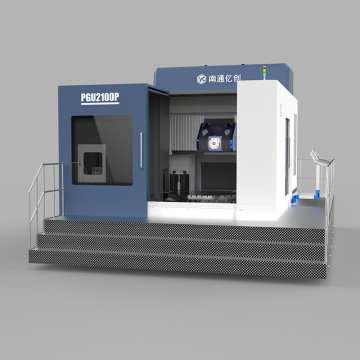

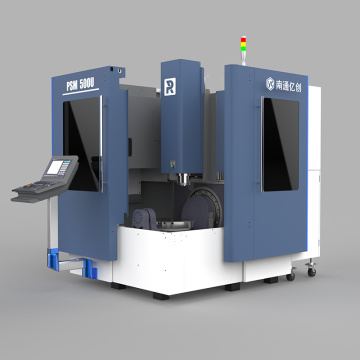

High Precision Gantry Machining Centers are becoming increasingly essential in the manufacturing industry, driven by the demand for precision and efficiency. These advanced machines, such as those produced by Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd., are designed to handle complex machining tasks with remarkable accuracy. The trend towards automation and smart manufacturing is further enhancing the value of these centers, making them a critical investment for companies aiming to improve production capabilities and reduce operational costs.

High Precision Gantry Machining Center

- manufacturer, factory, supplier from China(Total 12 Products for High Precision Gantry Machining Center)

-

Brand:YICHUANGAs a high-performance automated processing equipment, the gantry machining center has become a key equipment for many companies to improve production efficiency and reduce costs due to its excellent performance and wide range of applications....

-

Brand:YICHUANGThe overall structure of the gantry machining center is a portal frame, which is composed of a solid double column and a top beam. The middle crossbeam connects the two columns. This structure provides extremely high stability and rigidity, and can...

-

Brand:YICHUANGAs a high-performance automated processing equipment, the gantry machining center has become a key equipment for many companies to improve production efficiency and reduce costs due to its excellent performance and wide range of applications. On the...

-

Brand:YICHUANGCNC vertical turning machining center is a kind of CNC machine tool which integrates many machining capabilities such as turning, milling, drilling and tapping. Suitable for military, aerospace, automobile, mold, machinery manufacturing and other...

-

Brand:YICHUANGThe vertical machining center is a high-precision machine tool that can not only complete basic processes such as milling, boring, drilling, and tapping, but also perform complex three-dimensional surface processing and five-axis linkage processing....

-

Brand:YICHUANGThe five-axis gantry machining center provides excellent five-axis synchronous precision performance for five-axis machining such as mold cutting, high-precision contour finishing, milling, drilling, and tapping. The five-axis gantry CNC machine...

-

Brand:YICHUANGPerformance characteristics: ● The gantry five-axis machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, casings and other parts; ●...

-

Brand:YICHUANGPerformance characteristics: ● The 5-axis gantry vertical machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, special-shaped parts,...

-

Brand:YICHUANGPerformance characteristics: ● PSL series high precision profile processing center is suitable for military, aerospace, automobile, machinery manufacturing and other industries, and can complete the processing of narrow and long parts; ● CNC Profile...

-

Brand:YICHUANGHorizontal machining centers have a variety of types and a wide range of application fields to meet the needs of different industries for high-precision and high-efficiency machining. Performance characteristics: ● Horizontal machining center is...

-

Brand:YICHUANGThe PGU series five-axis gantry machining center adopts a high-rigidity structure with a moving beam gantry, which has a strong over-centering ability and is suitable for large-scale parts processing. The rotary table is a torque motor direct drive...

-

Brand:YICHUANGA horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. The horizontal machining center has the functions of automatically exchanging...

Innovative Applications of High Precision Gantry Machining Centers

High Precision Gantry Machining Centers are not only revolutionizing traditional manufacturing processes but also finding applications in aerospace, automotive, and medical device industries. These centers, like those offered by Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd., enable manufacturers to achieve tighter tolerances and higher efficiencies. As industries continue to evolve, the adoption of these machining centers is expected to grow, driven by the need for high-quality components and reduced lead times. This shift is indicative of a broader trend towards precision engineering and advanced manufacturing techniques.

| Industry | Market Size (Million USD) | Growth Rate (%) | Adoption Level (1-10) |

|---|---|---|---|

| Aerospace | 1200 | 8.5 | 9 |

| Automotive | 950 | 7.2 | 8 |

| Medical Devices | 650 | 9.1 | 7 |

| Electronics | 800 | 6.8 | 8 |

| Construction | 400 | 5.4 | 6 |

| Energy | 500 | 7 | 7 |

Video

Key Global Distributors of High Precision Gantry Machining Centers

The market for High Precision Gantry Machining Centers is witnessing significant growth globally, with key distributors playing a vital role in supply chain dynamics. As manufacturers seek to enhance their production capabilities, the demand for these machining centers is expected to rise. The trend towards digitalization and Industry 4.0 is also influencing the adoption of advanced machining technologies. Companies like Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. are at the forefront of this trend, providing innovative solutions that meet the evolving needs of various industries. The increasing focus on precision and efficiency is likely to drive market expansion in the coming years.

Related Information