-

Are you tired of wasting time on CNC parts that break easily? If you're a CNC machining novice facing frequent end mill breakage, you're not alone! Let's dive into some practical advice to turn your machining woes into wins. First off, if you're using a feed rate of .0075 in aluminum, that's quite substantial! Improper torque on the end mill in your ER32 holder might be the culprit behind those frustrating snap-offs. Remember, quality tools are your best friends—skip the cheap alternatives!

-

In the metal fabrication industry, Vertical Machining Centers (VMCs) are indispensable for achieving efficient milling operations, enabling operators to cut and shape materials with remarkable precision while minimizing manual intervention. VMCs come with a host of advantages, such as quick and easy setup processes, lower initial costs compared to their horizontal counterparts, and user-friendly operation, making them perfect for both prototyping and large-scale production runs. Their high ma

-

Are your Cnc Machined Parts letting you down again? If you’re like many in the machining world, you’ve probably faced the frustration of unexpected dimension variations that make you question your equipment—and your sanity. Take Sugumar, for instance, who reported a perplexing 20-micron shift after short b

-

Are you tired of production issues that slow down your business? Elevate your efficiency and quality with our precision CNC machined components! Don’t settle for less; choose our expert solutions to streamline your production process. Reach out to us today to explore how we can tackle your production challenges and enhance your operations. Whether you’re facing complex manufacturing tasks or need expert advice on material selection and machining processes, our skilled team is here to turn

The Rise of CNC Gantry Machining Centers in Modern Manufacturing

CNC Gantry Machining Centers are revolutionizing the manufacturing landscape by offering precision and efficiency in machining operations. As industries increasingly adopt automation and advanced manufacturing technologies, CNC Gantry Machining Centers have become essential for high-volume production. Companies like Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. are at the forefront of this trend, providing innovative solutions that enhance productivity and reduce operational costs. The ability to handle large workpieces with exceptional accuracy makes these machines invaluable in sectors such as aerospace, automotive, and heavy machinery.

Cnc Gantry Machining Center

- manufacturer, factory, supplier from China(Total 12 Products for Cnc Gantry Machining Center)

-

Brand:YICHUANGPerformance characteristics: ● The gantry five-axis machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, casings and other parts; ●...

-

Brand:YICHUANGThe overall structure of the gantry machining center is a portal frame, which is composed of a solid double column and a top beam. The middle crossbeam connects the two columns. This structure provides extremely high stability and rigidity, and can...

-

Brand:YICHUANGAs a high-performance automated processing equipment, the gantry machining center has become a key equipment for many companies to improve production efficiency and reduce costs due to its excellent performance and wide range of applications. On the...

-

Brand:YICHUANGThe five-axis gantry machining center provides excellent five-axis synchronous precision performance for five-axis machining such as mold cutting, high-precision contour finishing, milling, drilling, and tapping. The five-axis gantry CNC machine...

-

Brand:YICHUANGAs a high-performance automated processing equipment, the gantry machining center has become a key equipment for many companies to improve production efficiency and reduce costs due to its excellent performance and wide range of applications....

-

Brand:YICHUANGPerformance characteristics: ● The 5-axis gantry vertical machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, special-shaped parts,...

-

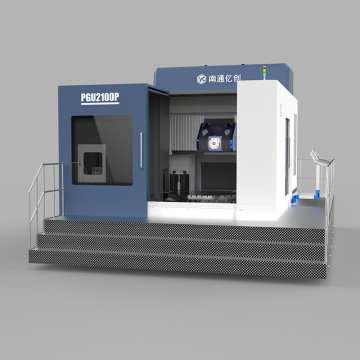

Brand:YICHUANGThe PGU series five-axis gantry machining center adopts a high-rigidity structure with a moving beam gantry, which has a strong over-centering ability and is suitable for large-scale parts processing. The rotary table is a torque motor direct drive...

-

Brand:YICHUANGCNC vertical turning machining center is a kind of CNC machine tool which integrates many machining capabilities such as turning, milling, drilling and tapping. ● High efficiency: Vertical turning machining centers are usually equipped with...

-

Brand:YICHUANGVertical machining center is a kind of high-precision machine tool, which can not only complete the basic procedures such as milling, boring, drilling and tapping, but also carry out complex three-dimensional surface machining and five-axis linkage...

-

Brand:YICHUANGA horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. The horizontal machining center has the functions of automatically exchanging...

-

Brand:YICHUANGHorizontal machining centers have a variety of types and a wide range of application fields to meet the needs of different industries for high-precision and high-efficiency machining. Performance characteristics: ● Horizontal machining center is...

-

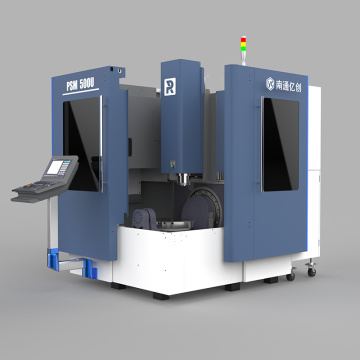

Brand:YICHUANGThe profile machining center is a high-performance automated processing equipment. Compared with ordinary CNC machine tools, its processing accuracy and stability have been significantly improved. It can meet customers' processing requirements for...

The Benefits of CNC Gantry Machining Centers for Large Components

CNC Gantry Machining Centers are particularly beneficial for machining large components due to their robust structure and high rigidity. These machines enable manufacturers to achieve tight tolerances and superior surface finishes, which are crucial for industries that require precision-engineered parts. Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. offers a range of CNC Gantry Machining Centers designed to meet the diverse needs of various industries, ensuring efficiency and quality in production processes. The versatility and adaptability of these machines allow manufacturers to optimize their workflows and respond quickly to market demands.

| Machine Model | Max Workpiece Size (mm) | Spindle Power (kW) | Price Range (USD) |

|---|---|---|---|

| Model A | 3000 | 15 | 50000 |

| Model B | 4000 | 18 | 70000 |

| Model C | 5000 | 20 | 90000 |

| Model D | 6000 | 25 | 120000 |

| Model E | 8000 | 30 | 150000 |

Video

Key Global Trends in CNC Gantry Machining Center Distribution

The global market for CNC Gantry Machining Centers is witnessing significant growth, driven by the increasing demand for precision machining in various sectors. As manufacturers seek to enhance productivity and reduce lead times, the adoption of these advanced machines is on the rise. Key players in the market are expanding their distribution networks to meet the growing demand. Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd. is actively engaging in international markets, ensuring that their cutting-edge CNC solutions are accessible to a broader audience. This trend is expected to continue as more companies recognize the value of investing in CNC technology for competitive advantage.

Related Information